WHEN it comes to the environmental future of floor screeds, now more than ever it’s incumbent on each and every one to contribute towards the environment in order to prevent irreversible global climate change.

The construction industry is no different. The sector is seeing a huge increase in demand for more sustainable materials, driven by not only the clients and consumers, but also government policy. Companies must continue to play a vital role in this process, by ensuring the operations and products it employs are as sustainable as possible.

LKAB Minerals says it’s leading the way towards a more sustainable future, now offering what it describes as some of the most environmentally-friendly materials in the UK market.

It says: ‘LKAB Minerals is the leading UK supplier of recycled anhydrite flowing floor screed materials; Gypsol and Gypsol Complete. The raw materials used in the manufacture of all Gypsol binders are harvested from an industry by-product.

‘By processing anhydrite for use as a binder, the process negates the need for landfill which, with it being calcium sulfate based, can cause ecological and environmental challenges needing careful management. 98% of Gypsol Binder is comprised of this recycled material; meaning for every one tonne of binder produced, 980kg of landfill is avoided.’

Because of the low temperature and energy required during the production process, LKAB Minerals says it’s minimised the carbon footprint associated with the manufacture of these binders to just 120kg per tonne of material produced, reportedly one of the lowest carbon contaminators in the UK floor screeding market.

When compared to a typical Portland cement based screed, about 85% of the embodied CO2 is avoided by simply changing to Gypsol screed, says the company.

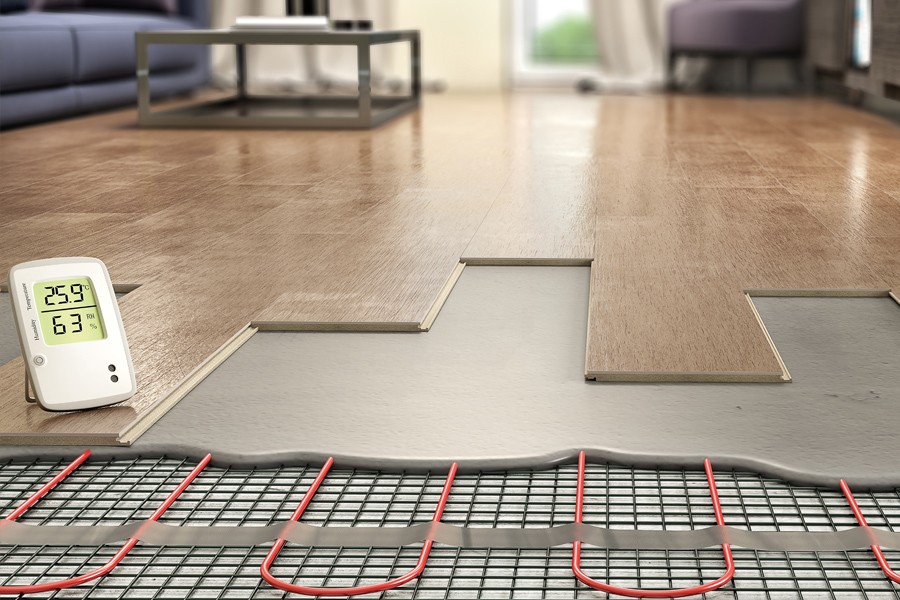

It continues: ‘Screeds made from Gypsol Binder can increase the optimal performance of underfloor heating systems, offering improvements in efficiency of over 25%. Gypsol screeds offer highly responsive properties with underfloor heating and require very low running temperatures, meaning they require very little energy input and providing comparatively high energy output.

‘In turn, this allows the highly efficient use of renewable heat technologies such as air source heat pumps. Heat pumps are generally capable of outputting water temperatures of about 40-45degC without the need for supplemental energy input, which may be required with a cement-based screed in the depths of winter; the very time when heating efficiency is of paramount importance. Tests have shown that for a house with a heat loss of about 80-90w/sq m, using Gypsol screed as the heat transfer medium required flow temperatures as low as just 30degC, to produce comfortable room temperatures of about 20degC.’

The company says Gypsol screeds can reduce the level and amount of building materials in a given building by reducing the depth requirements for the screed, with or without underfloor heating. Gypsol screeds can be laid at just 15mm depth compared to a typical sand cement screed, which must be at least 50mm deep in the same type of construction.

‘Where underfloor heating is present the minimum depth can be as little as 36mm compared to 75mm for a 1:4 cement sand screed. This can reduce the overall floor zone, and thus the building height (with commensurate material savings), or allows the use of deeper, more environmentally responsible insulations.

‘It’s well known that about 35% of the carbon emissions come from the home and The Climate Change Act requires that everybody contributes towards a more sustainable future. By 2025, fossil fuel heating systems in new houses will be a thing of the past and renewable heat technologies will become the norm.’

The company concludes: ‘The use of Gypsol in conjunction with such technologies can potentially reduce the carbon emissions from space heating to a point close to or below that required by the act.’

Please click to view more articles about

> LKAB Minerals <