2022 marked IFL’s 20th Anniversary. This milestone was celebrated with a 4-hour zoom call, attended by 28 colleagues across 8 countries. The theme of gratitude dominated the event. Gratitude for the past 20 years’ achievements, experiences, and memories. Moving speeches by colleagues and equally touching video messages from clients and service providers harnessed the family spirit of IFL and enthused the team with positivity and determination for the next 20 years.

MMFA Associate Member

Since Jan 2020, IFL has been a proud Associate Member of MMFA (Multilayer Modular Flooring Association), a European based organization representing leading producers of multilayer modular flooring and their supply industries. It is a platform for exchange of ideas and experiences which revolves around research, development and introduction of new Europe-wide standards and policies.

IFL’s blockchain based product passport system called TRUSST was presented to MMFA members as a potential bolt-on solution for achieving circular economy for flooring products; a subject gaining increasing significance.

| Markets Whilst China still retains its manufacturing powerhouse title, other Southeast Asian countries are growing their manufacturing capabilities and emerging as alternative, and in some cases, more competitive sources. Since 2019, IFL has been inspecting and testing engineered wood and LVT/SPC flooring from factories in South Korea, Vietnam, and Taiwan. These new markets complement IFL’s existing China-based operations and provide a more comprehensive offering for flooring businesses worldwide. |

| Quality Control Officer IFL is pleased to announce the promotion of a long-standing Senior Inspector, Mr. Zhang De Cai, to Quality Control Officer (QCO). Armed with 16 years of flooring focused inspection and quality control experience, Mr. Zhang is now based in IFL’s offices and laboratory in Dalian and supervises the maintenance and improvement of IFL Quality Control systems. He also coordinates Inspector training programs and supports the company’s drive towards a unified digitised system across its ERP, inspection and Lab testing platforms. |

Dimensional Accuracy &

Squareness Inspection Table (DASIT)

IFL has designed and built a tailor-made table to improve and expedite large scale dimensional accuracy and squareness inspection. Whether planks or blocks, it is essential for every flooring plank to be machined precisely within specified tolerances…read more.

Commonly Failed Tests

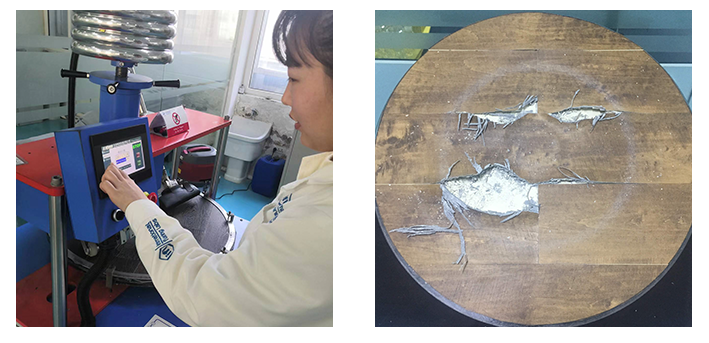

Castor Chair Test for LVT / WPC-core / SPC:

This International Standard test determines the durability of laminate and resilient flooring under constant use of castor chair wheels. This is a common and aggressive use-case most floors experience in real life that typically leads to damaged joints, detachment of internal layers and/or lifting of the plank itself. Correct raw material mix, internal structure properties and joint profile of planks determine the pass rate of this test. Non-conformity of these parameters can lead to serious failure of the flooring, as shown in the pictures below.