In our company’s 24-year history operating across China and Southeast Asia, we – along with the rest of the world – have weathered a fair share of macroeconomic challenges—SARS in 2003, the global financial crisis in 2008, and COVID in 2020, to name a few. But the pace of change today feels unprecedented. In fact, this message has been rewritten several times just to keep pace with rapidly evolving trade developments going on these days.

Just three months ago, at the Munich BAU exhibition, conversations centered on the EU’s anti-dumping taxes and their ripple effects across the wood flooring industry in both Asia and Europe. Now, as those issues continue to move through boardrooms in Europe, flooring businesses in the U.S. are contending with a new wave of fluctuating tariffs rolled out under the Trump administration.

There is never a dull moment in international trade. Amid these shifting dynamics, our clients are increasingly relying on IFL not just as a quality control company, but as a strategic partner in navigating uncertainty. In particular, our factory audits, pre-shipment inspections, and laboratory testing services are proving crucial in managing supply chain realignments and ensuring compliance.

We remain fully committed to strengthening our capabilities. Our laboratory is already ISO 17025 certified, and we are on track to achieve ISO 17020 certification for our inspection services by September. Meanwhile, our compliance team has completed in-depth training on the latest EUDR requirements, ensuring a seamless transition from EUTR to EUDR compliance for our clients.

Looking ahead to the upcoming DOMOTEX Asia exhibition, I’m optimistic. There is much to discuss, many ideas to crystallize, and countless ways we can continue supporting our clients through change.

On behalf of the entire IFL team, I extend my heartfelt thanks to our employees, clients, and partners around the world for your continued trust and collaboration.

Thank you.

by Farnam Sharifi – Founder & CEO

CSR Initiatives

Forced labour and child labour laws are on the rise, along with growing public awareness of Corporate Social Responsibility (CSR). In response, IFL provides CSR audits tailored to each client’s specific needs, ensuring compliance with relevant regulations and standards. These audits perform a formal review of a company’s social responsibility initiatives, operational procedures, and code of conduct, as well as their overall impact on society and the environment.

The on-site audit includes management and employee interviews, site observations, facility walk-throughs, and document reviews covering areas such as supply chain and raw material traceability, human rights, child labour, human trafficking, working hours, and health and safety.

The resulting report provides an assessment of how effectively the company is meeting its goals or benchmarks for operating as a socially responsible business. This is not a certification program but should be regarded as part of the importer’s due diligence process.

SPC Inspections

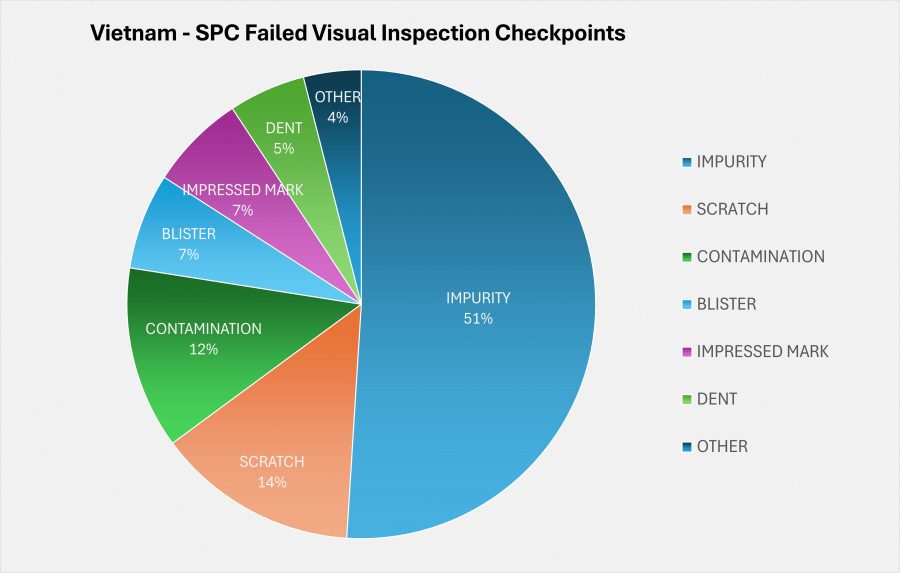

IFL inspectors, located around Vietnam in Hung Yen, Bac Ninh and Binh Duong, are experiencing an increase in their SPC flooring inspection volumes.

In addition to laboratory testing, visual inspection is a crucial component in ensuring the quality of SPC flooring. With our longstanding presence in Vietnam, IFL has conducted comprehensive SPC flooring inspections for many years, supporting manufacturers and buyers in the early detection and resolution of quality issues.

The accompanying pie chart illustrates the most frequently observed visual defects during inspections at one of Vietnam’s most representative SPC flooring factories, emphasizing the importance of a meticulous and proactive approach to quality control.

Texture Depth Measurement Device

The Texture Depth Measurement Device is a reliable and precise tool for evaluating the quality of textured surfaces on products such as SPC and laminate flooring with EIR (Embossed-In-Register) finishes, or wood flooring with brushed surfaces, where accurate texture depth is essential for both visual appeal and product performance.

A representative sample from the production batch is placed under the dial gauge needle. As the device is moved across the sample, it records the peaks and troughs of the surface features. These measurements provide a clear evaluation of the surface texture, supporting manufacturing accuracy in accordance with contract specifications and master samples, while also ensuring consistent production quality from batch to batch.

Locking Strength Test

Aside from the profile design itself, a flooring product’s locking system strength and performance is determined by the plank’s core material structural integrity and profile machining accuracy.

To guard against production-run deviations of these two important components, IFL performs several laboratory tests, for various flooring products, to evaluate the durability and reliability of locking joints under stress.

One such test is the Locking Strength Test, which determines the maximum force required to separate two interlocked planks and compares the results against benchmarked standards that help validate the locking system’s long-term performance.