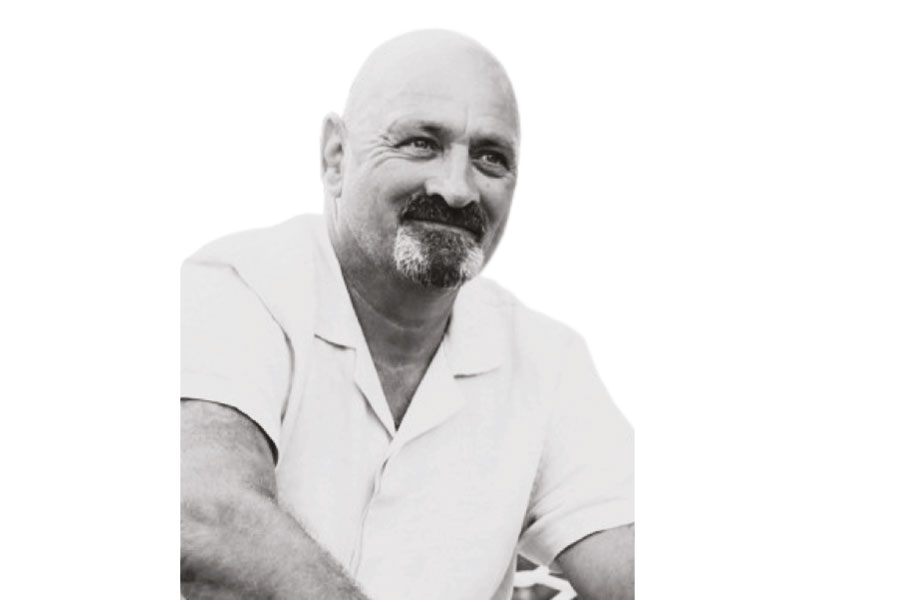

Kevin Field, commercial director ceramic & resilient products UK and Ireland, Mapei UK, says the company doesn’t look for cheaper alternatives with its raw materials

Q. Tell me a little about the history of your company.

A. Mapei is a world leading manufacturer of chemical products for the building industry. Together, these products form part of Mapei’s full system portfolio which offers a fully integrated building envelope solution that spans from foundation to roof. Mapei was founded in 1937 in Milan by Rodolfo Squinzi. Three generations of entrepreneurs have steered the business since then, with Marco and Veronica Squinzi at the helm since 2019.

Q. When and why did you join the company?

A. I actually came across Mapei products in my early years in the industry, in about 1981 when I joined GAAS flooring in Watford. A Mapei adhesive was then recommended for Altro products, AltroFix 19. To be honest, I couldn’t understand why Altro purchased its product from an Italian company.

As the years moved on, I started to understand the size and potential of Mapei in the UK market. I was fortunate to join Mapei in January 2004, with a single goal of putting the resilient products on the map. Some 22 years later, not only have we achieved the first goal but we have also built a strong team of people who’ve been instrumental in getting Mapei where we are today.

Both Phil Breakspear, managing director and myself made a promise to the then owner, Dr Squinzi, that we’d achieve sales in excess of £100m – daunting when, at the time, we were turning over £30m. Even to this day we believe it was euros but Giorgio Squinzi always said sterling. We’re fast approaching the £150m mark, with another target of £200m.

Q. Why are your company’s products different than your competitors’ products and what’s the secret to creating a successful flooring product?

A. Consistent quality backed by a strong team in all supporting departments such as production, marketing, customer service, technical support and, most importantly, a great training team that shows the correct way to install our products.

Mapei has very strong, robust processes to ensure the product is of the highest quality and we don’t look for cheaper alternatives with our raw materials – the product is Mapei. Our customers rely on the product being consistent which I believe is also so important. I can honestly say that in the 22 years of working for Mapei I cannot remember having any issues with products and that, to me, is why people use Mapei products.

Q. What’s the secret to a successful flooring installation?

A. This is by far the easiest question to answer – floor preparation. Every product manufactured, from a leveller to the final floorcovering, is only as good as what it’s adhered to. Do it right and do it once! Training, worldwide, from Mapei is so important to our success and the industry must continue to deliver.

Q. Who, outside your company, do you most admire in the industry?

A. After 40 years in the industry you work with some great businesses and people, so I would say it’s difficult to just say one. However, the first person to give me a chance in selling was Tim Sherwood from GAAS Flooring and then STS. Sadly, Tim passed away recently and my thoughts are with his daughter, Rachel and his family. RIP Tim and thanks for putting me on the path to where I am today.

Q. What three challenges do you feel the industry is facing and what are you doing to overcome these (sustainability, supply, consumer confidence, etc)?

A. Everyone faces different difficulties, from sustainable products to getting paid when the contractor has done a good job. For years, the industry has allowed the money to go out of the sector with cheaper products, so the end user can obtain a better price for their job. Average living costs increase and to run a successful contracting business must be tough, as most projects are price driven.

Q. Can you give an outline of your most popular product ranges and explain a bit about them?

A. Mapei has a vast array of products across so many different sectors, from waterproofing tunnels to products for the roof, so literally we can build a property from the ground upwards. If we talk about our resilient products then, again, full systems is key to offering a fully guaranteed solution for any floor or project. Our levelling compounds, I believe, are second to none in the market, with Ultraplan Renovation Screed 3240 being the best-selling leveller in the market today, backed up by three latex-mixed levellers – Latexplan Trade, Latexplan Fast and Latexplan No Ammonia. We continue, every year, to grow our business. To move to the next level we need to increase the sales on our adhesives; we all know how difficult it is to change habit but it can and will be done over the next few years.

Q. Is sustainability and ethical manufacturing a key commitment to your business, and if so, why?

A. Absolutely. Mapei is recognised, around the world, for its commitment to sustainability. Our products are manufactured with minimal waste outputs, reduced water consumption, sustainable raw materials, optimised packaging, low VOCs and a significantly reduced carbon footprint. More than 230 products are certified to international standards, including LEED, BREEAM and WELL, and over 500 have EPD certification.

Q. What innovation can your clients expect from you in the future?

A. Since the 1970s, Mapei has been at the forefront of manufacturing safe, solvent-free products. We continue to invest heavily in research and, as a world-wide supplier, we have to move with the times in every country, not just the UK.

Later this year, we’ve got five UK-made products joining the Zero Line, with CO2 Fully Offset in the Entire Life Cycle line. They include two adhesives – Ultrabond Eco V4 Evolution Zero and Ultrabond Eco 4 LVT Zero, Eco Prim T Plus Zero primer, Ultrabond Eco Tack TX+ Zero carpet tile tackifier and Ultraplan Eco 3215 Zero self-levelling compound.

Q. How robust is your supply chain in the face of global issues such as war?

A. Our supply chain was tested to the full during Covid-19 and, in what was a very difficult time for everyone, we managed to still supply our products. This was a true test of supply chain management. My biggest concern reference war is closer to home and it’s called the price war; too many good companies are trading high turnover figures with little profit. This isn’t sustainable and not good for the industry.

Q. What flooring trends are you seeing at the moment, and how do these influence your product development?

A. After 40 years in the industry, I have seen many trends come and go and usually the cycle changes every five-to-seven years. LVT is growing fast in the UK, which I believe is at the expense of carpet – I may be wrong – but there’s a place in the market for everything from linoleum and vinyl to laminate.

Mapei ensures we already have the products within our 8,100 worldwide portfolio.

We do not make a product because the UK has changed from carpet to LVT. We’ve been supplying other parts of the world with the correct product for years and just change the production to the UK, so we can supply the demand with a tried-and-tested system.

Q. Where do you see the company in five years?

A. Mapei’s clear strategy is to be number one in ceramic and stone installation products, and number one in products for the installation of resilient flooring in the UK. That’s where we’ll be before the five years are up.

info@mapei.co.uk

www.mapei.co.uk