FALLS are the most common cause of non-fatal injuries in the UK, with a significant portion linked to slips and trips. Choosing the wrong flooring can increase the risk, especially in areas prone to spills, moisture, or grease. This can have severe consequences for individuals, businesses, and healthcare systems, says SATRA.

What’s the key to prevention? A careful look at everything that affects the slip potential. Things to consider include the slip resistance of the flooring, the type of shoes people wear, the environment itself, potential spills, or grime, and how well the floor is cleaned and maintained.

Slip resistance testing

There are three common testing instruments used for assessing flooring products, and these are used across several test methods.

Pendulum method: EN 16165:2021 Annex C (formerly BS 7976-2)

This is the preferred testing instrument for slip resistance in the UK. It uses a swinging, imitation heel with different standardised rubber soling material to represent shod or barefoot use, which sweeps over a set area of flooring in a controlled manner. This test can be conducted in wet and dry conditions.

The company says: ‘The UK Slip Resistance Group (UKSRG) guidelines can also be used for this test, and the pendulum test value (PTV) result can be given a slip potential classification based on these guidelines.

The portability of this equipment allows assessment of in-situ flooring, to determine the continued suitability of the flooring, or whether contamination is having a significant effect.’

Ramp methods: EN 16165:2021 Annex A and EN 16165:2021 Annex B

In Europe, the ramp test methods are more favoured, says SATRA. These involve test subjects walking over a contaminated flooring sample, forwards and backwards, with a gradually increasing inclination until the test subject slips. The average angle of inclination can then be classified against the tables included in the German National Annex to the EN 16165:2021 standard.

In Annex A, a soap solution is used as the contaminant, with the operators walking barefoot on the sample. In Annex B, motor oil is the contaminant, and the operators wear heavily cleated safety boots. In the UK, there are reservations about these methods, as they don’t represent common uses of flooring, and the way the results are reported can cause some confusion, says the company.

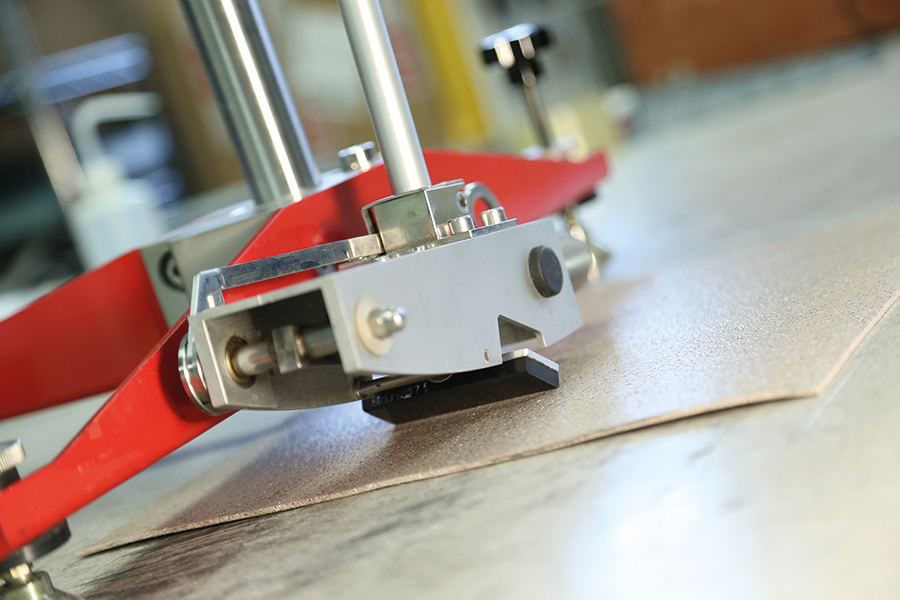

Tribometer method: EN 13893:2002

This method uses a self-powered trolley, which drags itself across the floor surface. The company adds: ‘The test doesn’t recreate the conditions of pedestrian gait, which give rise to most slip accidents, and is therefore unlikely to be relevant to a pedestrian slipping in contaminated conditions.

However, this method remains important, as for resilient, laminate, and modular multilayer materials, which have been CE or UKCA marked against the Construction Product Regulations, the harmonised/designated standard EN 14041:2004/AC:2006 requires this test method is used if a claim for slip resistance is made.’

floorcoverings@satra.com